Common Aircon Abbreviations

Understanding the Basics

Air conditioning systems come with a host of terms and abbreviations that can be confusing. Whether you’re a homeowner, technician, or someone interested in air conditioning. Knowing these terms can enhance your understanding of how air conditioning systems function, enabling you to make more informed decisions regarding installation, maintenance, and upgrades. Here’s a breakdown to help you understand the most common ones and make sense of your aircon’s components and efficiency.

General Air Conditioning Terms

AC (Air Conditioning)

Explanation:

Air conditioning refers to the system or process that controls the temperature, humidity, and air quality in a space. It provides comfort, better air quality, and protects equipment from overheating. The primary purpose of air conditioning is to maintain a comfortable indoor environment. This is achieved by removing excess heat and moisture from the air, ensuring a controlled and cool atmosphere. Moreover, air conditioning has important secondary effects, such as reducing the risk of heat-related health issues and improving indoor air quality by filtering out pollutants and allergens.

Key Benefits:

- Comfort: Air conditioning helps maintain a cool, comfortable indoor temperature, even on the hottest days.

- Better Air Quality: It filters out pollutants and allergens, improving overall air quality.

- Health and Safety: Reduces the risk of heat-related health issues, such as heatstroke and dehydration.

- Equipment Protection: Prevents sensitive equipment from overheating, which can lead to malfunctions or damage.

Usage:

Common in homes, offices, and commercial spaces to provide a safe and comfortable indoor environment.

ACMV (Air Conditioning & Mechanical Ventilation)

Explanation:

ACMV systems are essential in providing thermal comfort and ensuring healthy air quality in both residential and commercial buildings. These systems control the temperature, humidity, and cleanliness of the air within a building. A well-designed ACMV system includes components such as chillers, air handling units, fans, filters, ducts, and control systems. The primary function of ACMV is to maintain a comfortable indoor environment by supplying clean, conditioned air while removing stale air from the interior spaces. It also helps regulate the moisture level within the space to prevent mold growth and other moisture-related issues .

Usage:

In buildings such as offices, shopping malls, hospitals, and schools, ACMV systems are used to create an optimal indoor environment that supports the occupants’ well-being and productivity. In a manufacturing plant, an ACMV system is used to ensure that both the equipment and the workers operate in a controlled environment, which is crucial for quality control and safety. In residential settings, ACMV systems provide comfort and improve the air quality in living spaces, helping to prevent health issues related to poor indoor air quality.

BTU (British Thermal Unit)

Explanation:

The British Thermal Unit (BTU) is a unit of heat energy that is commonly used in the power, steam generation, heating, and air conditioning industries. It is defined as the amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit at a constant pressure of one atmosphere. One BTU is equivalent to approximately 1,055 joules. The BTU is often used to describe the energy content of fuels and the power of heating and cooling systems. For example, the heat output of a furnace or the cooling capacity of an air conditioner is typically measured in BTUs per hour (BTU/hr) .

Usage:

In the HVAC industry, BTU ratings are used to determine the capacity of heating and cooling systems. For instance, when selecting an air conditioner, the BTU rating indicates how much heat the unit can remove from the air per hour. A higher BTU rating means greater cooling capacity, which is necessary for larger rooms or spaces with higher heat loads. Similarly, in heating systems, the BTU rating indicates the system’s ability to generate heat. This helps homeowners and contractors choose the appropriate size of heating or cooling equipment to ensure optimal performance and energy efficiency.

CFM (Cubic Feet per Minute)

Explanation:

CFM, or Cubic Feet per Minute, is a unit of measurement used in HVAC systems to describe the volume of air flow. It represents the amount of air that can be moved or circulated by a system in one minute. The CFM rating of an HVAC system or component, such as a fan or duct, determines how quickly and effectively air is distributed throughout a space. An appropriate CFM ensures that air is circulated evenly, maintaining a consistent and comfortable indoor environment. In HVAC design, achieving the right CFM is crucial to prevent issues like hot or cold spots, and to ensure efficient operation of the system.

Usage:

CFM is used to evaluate the performance of ventilation systems, air conditioners, and heating systems. For example, when installing a ventilation system in a commercial kitchen, calculating the CFM helps ensure that the system can adequately remove heat, smoke, and odors from the cooking area. In residential settings, the CFM rating of an HVAC system is used to determine the size and type of equipment needed to maintain comfortable indoor temperatures. In industrial applications, CFM is used to design systems that can handle the specific air flow requirements of the facility, such as in clean rooms or manufacturing plants.

EER (Energy Efficiency Rating)

Explanation:

The Energy Efficiency Ratio (EER) is a metric used to measure the energy efficiency of cooling devices, such as air conditioners and heat pumps. It is calculated by dividing the cooling capacity of the unit (measured in BTUs per hour) by its power consumption (measured in watts) under specific conditions. A higher EER indicates a more energy-efficient device. EER is typically used to compare the energy efficiency of different models and types of cooling systems, helping consumers and businesses make informed decisions about their energy usage and environmental impact. EER values are usually higher in devices that use advanced technologies and materials to maximize efficiency and reduce energy consumption. A higher EER means better efficiency. In Singapore, the NEA rates EER from 1 to 5 ticks, with 5 being the most efficient.

Usage:

EER is used by consumers and businesses to evaluate and compare the energy efficiency of air conditioning units and heat pumps. When purchasing a new cooling system, buyers often look for models with a high EER to minimize energy costs and reduce their environmental footprint. In commercial settings, businesses use EER to select equipment that meets their cooling needs while also aligning with sustainability goals. Additionally, utility companies and government agencies may use EER as a basis for offering incentives or rebates to encourage the adoption of energy-efficient technologies.

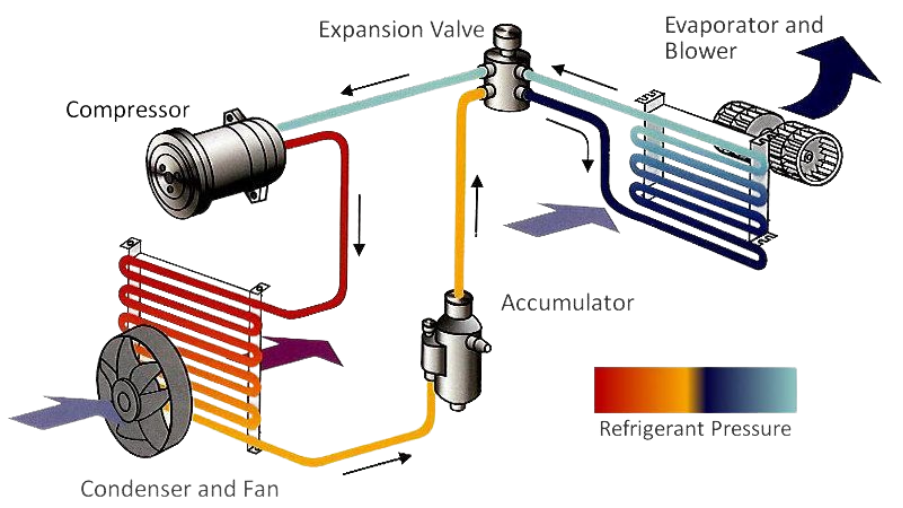

Key System Components

These components are crucial for the operation of your air conditioning system, with each playing a specific role in ensuring effective cooling and ventilation.

FCU (Fan Coil Unit)

These components are crucial for the operation of your air conditioning system, with each playing a specific role in ensuring effective cooling and ventilation.

Explanation:

A Fan Coil Unit (FCU) is a device that circulates air within a space to provide heating and cooling. It consists of a fan and a heat exchanger, through which hot or cold water is circulated. The fan draws air from the room and passes it over the heat exchanger, where it is either heated or cooled before being recirculated back into the room. FCUs are a popular choice for providing localized temperature control in buildings because they are relatively easy to install and maintain. They can be used in conjunction with a central HVAC system or as standalone units, offering flexibility in design and operation .

Usage:

EER is used by consumers and businesses to evaluate and compare the energy efficiency of air conditioning units and heat pumps. When purchasing a new cooling system, buyers often look for models with a high EER to minimize energy costs and reduce their environmental footprint. In commercial settings, businesses use EER to select equipment that meets their cooling needs while also aligning with sustainability goals. Additionally, utility companies and government agencies may use EER as a basis for offering incentives or rebates to encourage the adoption of energy-efficient technologies.

CU (Condenser Unit)

Explanation:

A Condensing Unit (CU) is a vital component of an HVAC system that plays a critical role in the cooling process. It comprises a compressor, condenser coil, and fan, all of which work together to convert the refrigerant from a gas to a liquid and then expel the heat outside. The CU is typically located outdoors and is responsible for releasing the heat absorbed from the indoor environment. By removing excess heat, the CU helps maintain comfortable indoor temperatures and prevents overheating of spaces. Proper maintenance and regular inspection of the CU are essential to ensure the efficiency and longevity of the entire HVAC system

Usage:

Condensing units are used in various applications, including residential, commercial, and industrial settings. In residential homes, CUs are part of split air conditioning systems, where the indoor unit absorbs heat from the interior and transfers it to the outdoor CU for expulsion. In commercial buildings, CUs are used in large HVAC systems to manage the cooling needs of multiple rooms or zones. In industrial applications, CUs are used to control the temperature of manufacturing processes, equipment, and products, ensuring quality control and safety.

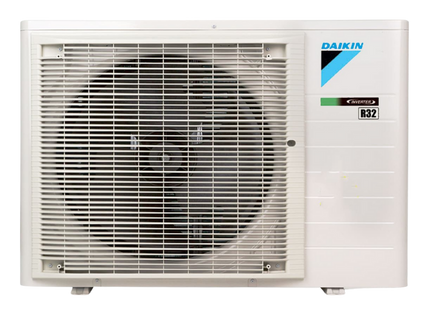

VRV (Variable Refrigerant Volume)

Explanation:

VRV is a technology that alternates the refrigerant volume within a system to match the precise cooling or heating needs of different zones in a building. Developed by Daikin, VRV systems are designed to provide energy-efficient and customizable climate control. By varying the refrigerant flow, the system can adjust its output based on the occupancy and temperature requirements of each zone, reducing energy consumption and improving comfort. VRV systems also feature advanced control systems that monitor the operation of individual units and optimize performance for maximum efficiency and comfort.

Usage:

VRV systems are used in commercial buildings, such as offices, hotels, and retail spaces, where there is a need for precise and flexible temperature control. For example, in a multi-story office building, a VRV system can provide different temperature settings for each floor or department, ensuring that each area is comfortable and energy-efficient. In hotels, VRV systems allow guests to adjust the temperature of their rooms to their liking, enhancing their comfort and satisfaction. In retail spaces, VRV systems help maintain optimal temperatures for both customers and merchandise, ensuring a pleasant shopping experience and product preservation.

VRF (Variable Refrigerant Flow)

Explanation:

Variable Refrigerant Flow (VRF) is an HVAC technology that uses refrigerant as the cooling and heating medium, circulating it through multiple indoor units to provide individualized comfort in different zones of a building. The system can vary the flow of refrigerant to each indoor unit based on the specific needs of each zone, ensuring optimal performance and energy efficiency. VRF systems are known for their flexibility, allowing for simultaneous heating and cooling in different areas, and their ability to maintain precise temperature control. These systems are also quieter and more space-efficient compared to traditional HVAC systems

Usage:

VRF systems are commonly used in commercial and residential buildings where there is a need for flexible and efficient temperature control. In office buildings, VRF systems allow for different temperature settings in various departments or individual offices, enhancing employee comfort and productivity. In residential settings, VRF systems provide homeowners with the ability to control the temperature of each room independently, reducing energy costs and improving comfort. In hotels, VRF systems allow guests to adjust the temperature of their rooms to their preferences, enhancing their overall experience.

Refrigerants and Coolants

Refrigerants are the lifeblood of air conditioning systems, and understanding the differences can help you make more environmentally conscious choices.

R-22 (Refrigerant 22)

Explanation:

R-22, also known as Freon-22, is a hydrochlorofluorocarbon (HCFC) refrigerant that was widely used in air conditioning and refrigeration systems. Due to its ozone-depleting properties, the production and import of R-22 have been phased out in many countries under the Montreal Protocol. As a result, R-22 is being replaced by more environmentally friendly refrigerants, such as R-410A and R-407C. While R-22 is still used in existing systems, its availability is decreasing, and its price is rising due to the phase-out. This has led many businesses and homeowners to retrofit or replace their old R-22 systems with newer, more efficient ones

Usage:

R-22 was commonly used in residential and commercial air conditioning systems, as well as in refrigeration systems for supermarkets, cold storage facilities, and food processing plants. In older systems, R-22 is still used as a refrigerant to provide cooling and heating. However, due to the phase-out, businesses and homeowners with R-22 systems are advised to transition to newer systems that use alternative refrigerants. This helps reduce the environmental impact of ozone-depleting substances and ensures compliance with regulations.

R-410A (Refrigerant 410A)

Explanation:

R-410A is a hydrofluorocarbon (HFC) refrigerant that is used as a replacement for R-22 in air conditioning and refrigeration systems. It is more energy-efficient and environmentally friendly compared to R-22, as it does not contribute to ozone depletion. R-410A operates at higher pressures than R-22, which requires the use of different equipment and components designed to handle the increased pressure. R-410A systems are known for their improved energy efficiency, better cooling performance, and reduced environmental impact, making them a popular choice for new installations and retrofits

Usage:

R-410A is used in a wide range of applications, including residential and commercial air conditioning systems, heat pumps, and refrigeration systems. In residential settings, R-410A systems provide efficient cooling and heating, helping homeowners reduce their energy costs and environmental footprint. In commercial buildings, R-410A is used in HVAC systems to provide reliable and efficient temperature control for offices, retail spaces, and other facilities. In industrial applications, R-410A is used in refrigeration systems to maintain optimal temperatures for food storage, manufacturing processes, and other critical applications.

R-32 (Refrigerant R32)

Explanation:

R-32, also known as Difluoromethane, is a refrigerant used in HVAC systems. It belongs to the category of Hydrofluorocarbons (HFCs) and is known for its lower Global Warming Potential (GWP) compared to other commonly used refrigerants like R-410A and R-22. R-32 has a GWP of 675, making it a more environmentally friendly option. It is efficient in terms of cooling performance and allows for a reduction in the amount of refrigerant needed in an HVAC system. R-32 is compatible with existing technologies, making it a popular choice for new installations and retrofitting older systems.

Usage:

R-32 refrigerant is used in various types of air conditioning and refrigeration systems to provide efficient cooling while minimizing environmental impact:

- Residential Air Conditioners: R-32 is used in split-system and window air conditioners to provide cooling with reduced energy consumption and a lower environmental footprint.

- Commercial HVAC Systems: In commercial buildings, R-32 is used in rooftop units, chillers, and other large-scale HVAC systems to enhance energy efficiency and reduce GWP.

- Refrigeration Systems: R-32 is used in supermarket refrigeration systems, cold storage facilities, and other applications where environmentally friendly refrigeration solutions are needed.

- Automotive Air Conditioning: R-32 is being explored as a potential replacement for R-134a in automotive air conditioning systems to meet environmental regulations.

Operational Terms

These terms are essential for understanding the efficiency, safety, and air quality aspects of air conditioning systems.

COP (Coefficient of Performance)

Usage:

The COP is used in various applications to assess the energy efficiency and performance of heating and cooling systems:

- • HVAC System Comparison: COP is used to compare the energy efficiency of different types of HVAC systems, such as air conditioners, heat pumps, and boilers. Systems with higher COP values are considered more energy-efficient.

- • Energy Consumption Analysis: COP is used to calculate the energy consumption of heating and cooling systems and to estimate the operating costs of these systems.

- • Performance Testing: COP is used in performance testing of HVAC equipment to ensure that the systems meet the required efficiency standards and specifications.

- • System Design and Optimization: COP is used in the design and optimization of HVAC systems to select the most energy-efficient equipment and to determine the best operating conditions for maximizing efficiency.

Explanation:

The Coefficient of Performance (COP) is a measure of the efficiency of a heating or cooling system. It is defined as the ratio of the useful heating or cooling provided to the energy consumed by the system. A higher COP indicates a more efficient system, as it provides more heating or cooling for the same amount of energy input. The COP can vary depending on the operating conditions, such as the temperature of the indoor and outdoor environments. COP is commonly used to compare the efficiency of different HVAC systems and to determine the energy efficiency of heating and cooling equipment.

IAQ (Indoor Air Quality)

Explanation:

Indoor Air Quality (IAQ) refers to the quality of the air inside buildings and structures as it relates to the health and comfort of the occupants. It’s a key aspect of Singapore’s Greenmark criteria.IAQ is affected by various factors, including the concentration of pollutants, humidity levels, temperature, and ventilation. Poor IAQ can lead to health problems such as allergies, asthma, and respiratory infections. Improving IAQ involves controlling the sources of indoor pollutants, maintaining proper ventilation, and using air purification systems to remove contaminants from the air.

Usage:

IAQ is a critical consideration in various applications to ensure the health and comfort of building occupants:

- Residential Homes: IAQ is important in homes to prevent health issues related to poor air quality, such as allergies and respiratory problems. Homeowners can improve IAQ by using air purifiers, maintaining proper ventilation, and controlling sources of indoor pollutants.

- Commercial Buildings: In commercial buildings, IAQ is essential for the health and productivity of employees and customers. Building managers can improve IAQ by implementing ventilation systems, using low-emission building materials, and maintaining clean and well-functioning HVAC systems.

- • Hospitals: In healthcare facilities, IAQ is critical for preventing the spread of infections and ensuring the safety of patients and staff. Hospitals use advanced air purification and ventilation systems to maintain high IAQ standards.

- • Schools: IAQ is important in schools to provide a healthy learning environment for students and teachers. Schools can improve IAQ by using proper ventilation systems, controlling moisture and humidity levels, and minimizing the use of chemicals and pollutants.

- • Industrial Facilities: In industrial facilities, IAQ is important for the safety and well-being of workers. Facilities can improve IAQ by using proper ventilation systems, controlling sources of pollutants, and providing personal protective equipment (PPE) to workers.

OEM (Original Equipment Manufacturer)

Explanation:

An Original Equipment Manufacturer (OEM) is a company that produces parts or components that are used in another company’s end product. In the context of HVAC systems, an OEM may manufacture parts such as compressors, motors, and other components that are used in the assembly of air conditioners, furnaces, and other HVAC equipment. OEMs play a crucial role in the supply chain by providing high-quality components that meet the specifications and standards required by the equipment manufacturers.

Usage:

OEMs are involved in various applications related to the production and assembly of HVAC systems and components:

- • HVAC System Production: OEMs manufacture key components such as compressors, motors, fans, and heat exchangers that are used in the production of HVAC systems. These components are then assembled by the equipment manufacturers to create the final products.

- • Replacement Parts: OEMs provide replacement parts for HVAC systems, ensuring that the components meet the original specifications and standards. This helps maintain the performance and efficiency of the systems.

- • Customization and Integration: OEMs work with equipment manufacturers to customize components and integrate them into the final products. This allows for the development of specialized HVAC systems that meet specific requirements and applications.

• Quality Assurance and Testing: OEMs conduct quality assurance and testing of components to ensure that they meet the required standards and specifications. This helps ensure the reliability and performance of the HVAC systems.

PPE (Personal Protective Equipment)

Explanation:

Personal Protective Equipment (PPE) refers to the equipment worn by individuals to protect themselves from hazards in the workplace. In the context of HVAC systems, PPE is used by technicians, installers, and maintenance personnel to protect themselves from potential hazards such as exposure to refrigerants, electrical hazards, and physical injuries. PPE includes items such as safety glasses, gloves, respirators, hard hats, and protective clothing, which are designed to provide protection against specific hazards.

Usage:

PPE is used in various applications related to the installation, maintenance, and repair of HVAC systems to ensure the safety of workers:

- • Installation and Maintenance: HVAC technicians use PPE such as safety glasses, gloves, and protective clothing when installing and maintaining HVAC systems to protect themselves from exposure to refrigerants, electrical hazards, and sharp edges.

- • Refrigerant Handling: When handling refrigerants, technicians use PPE such as gloves and respirators to protect themselves from exposure to chemicals and gases that can be harmful to their health.

- •Electrical Work: Technicians use PPE such as insulated gloves and safety glasses when working with electrical components of HVAC systems to protect themselves from electrical hazards and injuries.

- •Confined Spaces: When working in confined spaces, such as air ducts or crawl spaces, technicians use PPE such as respirators and protective clothing to protect themselves from dust, mold, and other contaminants.

- • Safety Training and Compliance: HVAC companies provide safety training and ensure compliance with safety regulations by providing appropriate PPE to their workers and enforcing its use in the workplace.

| Aspect | Description | Importance | Usage |

|---|---|---|---|

| General Terms | |||

| AC (Air Conditioning) | Controls temperature, humidity, and air quality. | Essential for indoor comfort. | Homes, offices, commercial spaces. |

| ACMV (Air Conditioning & Mechanical Ventilation) | Includes air conditioning and ventilation systems. | Ensures indoor air quality and safety. | Large commercial buildings. |

| BTU (British Thermal Unit) | Unit of heat energy; describes cooling capacity. | Helps select the right AC size. | Matching AC capacity with area size. |

| CFM (Cubic Feet per Minute) | Measures air volume moved per minute. | Ensures effective ventilation. | Designing HVAC systems. |

| EER (Energy Efficiency Rating) | Efficiency metric for air conditioners. | Critical for energy conservation. | Comparing AC unit efficiency. |

| System Components | |||

| FCU (Fan Coil Unit) | Indoor component; cools or heats air. | Provides localized cooling/heating. | Residential and commercial HVAC systems. |

| CU (Condenser Unit) | Outdoor component; expels heat. | Essential for heat exchange. | Outside building installations. |

| VRV (Variable Refrigerant Volume) | Multi-split system; varies refrigerant flow. | Offers flexibility and energy savings. | Large buildings, hotels, offices. |

| VRF (Variable Refrigerant Flow) | Similar to VRV; precise temperature control. | Provides energy efficiency. | Applications similar to VRV. |

| Refrigerants and Coolants | |||

| R-22 (Refrigerant 22) | Older refrigerant; phased out. | Historically used, now harmful to ozone. | Being replaced by greener alternatives. |

| R-410A (Refrigerant A10A) | Efficient refrigerant; being phased out. | Offers better energy efficiency. | Common in newer AC systems. |

| R-32 (Refrigerant R32) | Primary refrigerant; eco-friendly. | Step towards sustainable A.C. | Standard for AC systems in Singapore. |

| Operational Terms | |||

| COP (Coefficient of Performance) | Efficiency ratio; higher COP = better efficiency. | Evaluates energy efficiency. | HVAC system design and selection. |

| IAQ (Indoor Air Quality) | Air quality within a building. | Maintains a healthy indoor environment. | Residential and commercial buildings. |

| OEM (Original Equipment Manufacturer) | Parts made by original manufacturer. | Ensures compatibility and reliability. | Supply and maintenance of HVAC systems. |

| PPE (Personal Protective Equipment) | Safety gear for technicians. | Essential for technician safety. | Maintenance and installation scenarios. |